What is SmartCorrect™?

SmartCorrect™ Gauging system is an automation device that is set to revolutionize the manufacturing industry. It is a plug and play device that can be attached to any legacy CNC Lathe machine and transform it into a “smart machine“.

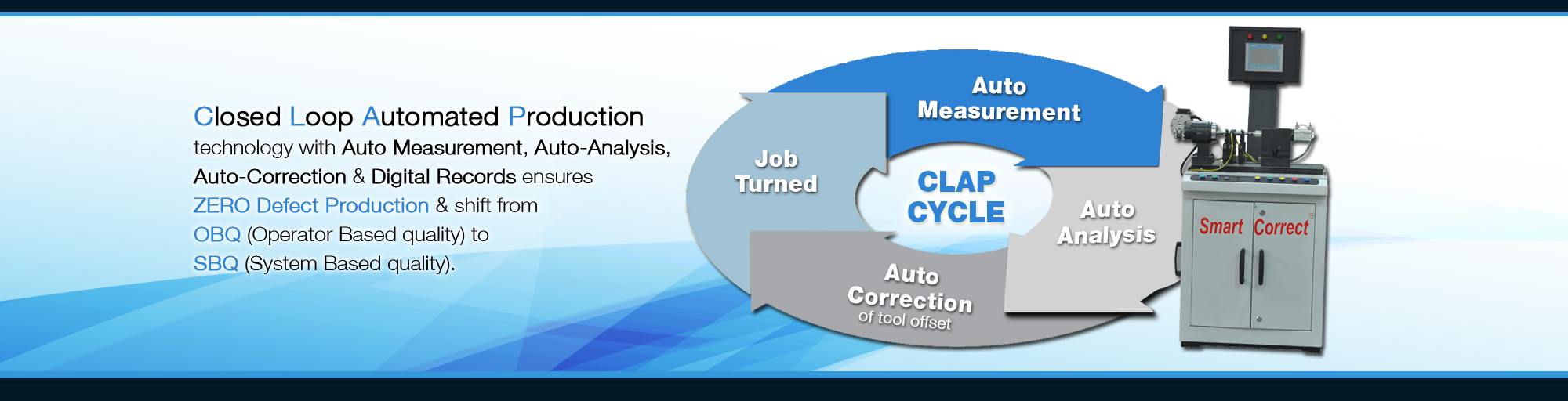

SmartCorrect™ Gauging Systems employ Marshall’s patented “Closed Loop” technology ensuring Zero Defect Production of manufactured parts.

What is CLAP?

‘CLOSED LOOP’ turning means that job is automatically inspected, dimensions auto-analyzed, feedback is given automatically and machine is auto-corrected.

The traditional method of turning is called ‘OPEN LOOP’ because there is no automatic feedback of the dimensions produced on a part to the CNC lathe. A human operator measures the job and decides which dimension requires alteration/correction and by how much, which can lead to measurement errors, judgement errors or input errors resulting in production of defective parts.

SmartCorrect™ (Patent Applied) is a Gauging Station which implements Closed Loop turning by :

- Auto-measuring important dimensions of the job with Touch Probes, Lasers, etc.

- Auto-analyzing measurements with its special algorithms.

- Auto-correcting the CNC by sending correction values, as and when required.

- Auto-recording the measured dimensions

The Algorithms used in SmartCorrect™ always keep the process mean for all measured dimensions very close to their respective Tolerance means by making corrections to the wear offsets of the tools. This ensures that Cpk> 0.9xCp which ensures near zero defects.

Yes. SmartCorrect™ has capacity to interface with almost all popular CNC Controllers like FANUC, SIEMENS, MITSUBISHI, HEIDENHAIN, etc. It can be plugged into any existing (legacy) CNC Lathe to convert it into a smart machine.

SmartCorrect™ uses parts from the best manufacturers in the world (MARPOSS, OMRON, HEIDENHAIN, SCHNEIDER) . Since this is a measuring system (Gauging Station) there are no chances of any damage unless there is a mishap, in which case the damaged part can be easily replaced. And this is only for the parts coming in contact with the job like Touch Probes or elements.

Other parts like pneumatic & moving elements like LM guides need periodic inspection and maintenance.